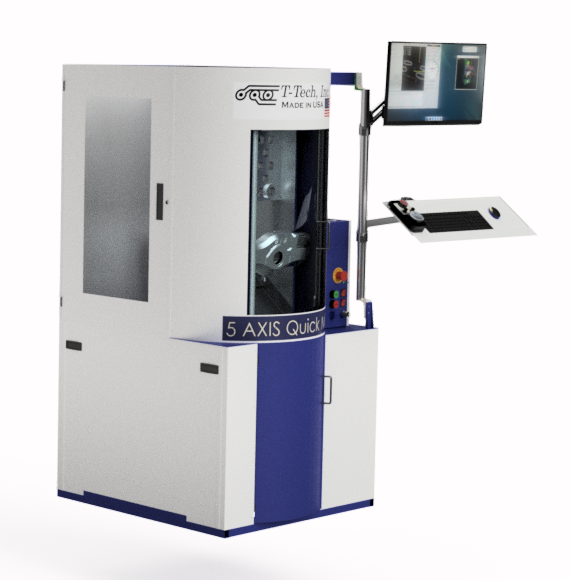

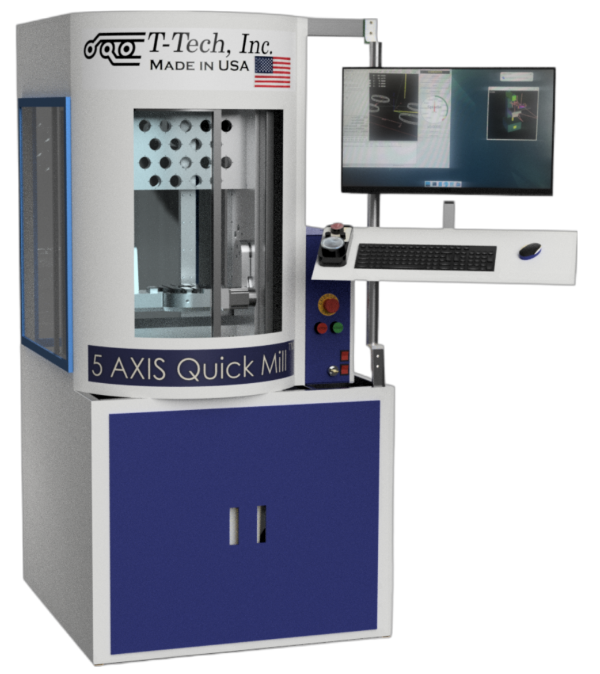

T-Tech, Inc. announces our new 5 Axis Quick Mill ™. The 5 Axis Quick Mill ™allows a mechanical engineer to make metal parts. The five-axis motion allows for complex shapes and geometries developed by your design team with your CAD/CAM software. Purchase a 5 Axis Quick Mill™, design a part, and make it in your office! The Quick Mill is Made in the USA.

The 5 Axis Quick Mill has a work area of 8” x 8” x 8” with 21 automatic tool change locations. The 24,000 RPM spindle is liquid cooled. It has a three-horsepower spindle and due to the high RPM, you may program a light finishing cut with extreme accuracy. The tool tip sensor measures the length of each tool in the setup, so the 5 Axis Quick Mill has true tool point center control. The software always knows where the tool is in relationship to your material coordinate system. The viewing camera is pointed at the work area so you can watch the mill work remotely using our web application. The tool probe uses a wireless signal to detect the probe when it is measuring the material.

The 5 Axis Quick Mill has intuitive software that runs in a Linux operating environment. It uses an embedded computer system that has open-source software installed and configured for the Quick Mill controls. We have created menus for simplicity and streamlining operations.

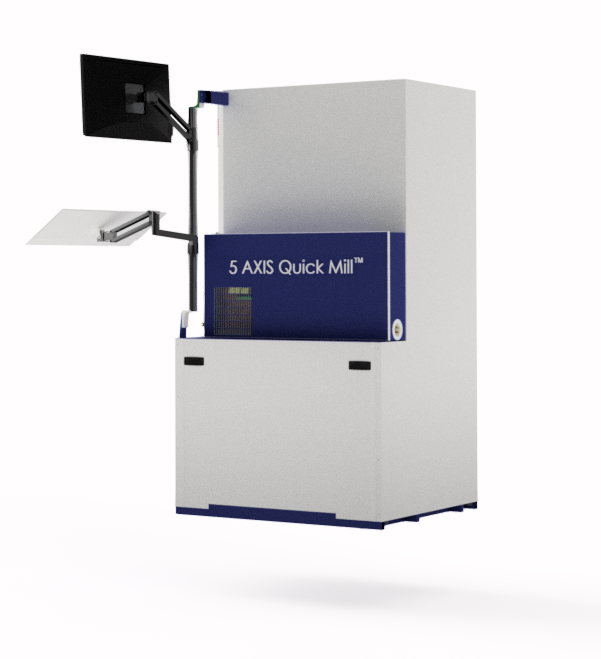

The 5 Axis Quick Mill is completely self-contained. It will fit through a standard door. When you install it all you need to do is level the machine and plug it in. It requires a 220-volt, single phase, 20-amp outlet. Of course, you will need to put the coolant in the coolant tank. We have supplied a wall outlet and power cord for your convenience.

5 Axis Quick Mill™ Technical Specifications

The 5 Axis Quick Mill™ fits through a standard doorway and requires only basic setup: leveling, plugging into a 20 amp, 220-volt outlet, and filling the coolant reservoir. A wall outlet and proper power cord are included for convenience.

Available Distribution

Click for a complete list of distributors and sales representatives.

- Locally Distributed By:

- T-Tech, Inc.

- 51 Rocky Road Industrial Loop

- Driggs, Idaho 83422

- sales@t-tech.com

- 770-455-0676

- September 24, 2025

Photo Gallery

Click for larger image.